Visit the post for more. Printable Weekly Checklist Template Por Eyewash Station Eyewash station weekly checklist itu absorbtech first aid inspection sheet of a station fill online printable fillable access is everything eyewash stations showers must be ready when eyewash station weekly checklist emergency. Jul 5, 2011 - Plumbed eyewash stations require weekly checks to be compliant with ANSI Z358.1-2009, which OSHA may reference during an inspection.

By: July 5th, 2011 Here is a tip from the July issue of Medical Environment Update, which featured OSHA compliance and emergency eyewash stations in medical and dental practices. Plumbed eyewash stations require weekly checks to be compliant with ANSI Z358.1-2009, which OSHA may reference during an inspection. Raptor reliability simulation software software free download free.

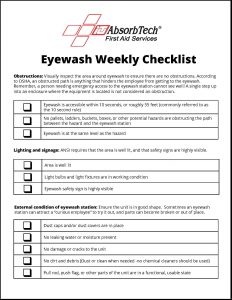

Each week, check for the following: • Access and signage. Eyewash stations must be easily identifiable and unobstructed. Turn on the station and check that: — The station activates easily with foot or one-handed control — The flow removes eyepiece covers — Water flows evenly in a steady stream from both eyepieces • Flush. Run the station for three minutes to flush stagnant water from the line. • Eyepiece cover disinfection.

Rinse covers according to manufacturers’ instructions or with 10% bleach solution. Flush with water for 15 seconds, then replace. Source: OSHA Program Manual, HCPro, 2011. Get in to compliance with HCPro’s Basic OSHA Compliance Manual Kits for or practices.

Receive bimonthly electronic manual updates that keep your regulatory manual up to date and in compliance! Medical Environment Update is an eight-page monthly designed to help busy healthcare professionals who don't have time to look through regulatory journals for compliance requirements and information. MEU has written 123 posts.• Categories • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Archives • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • Feeds • •.

Emergency Eyewash Station If you are responsible for conducting eyewash station checks at your facility, we recommend using an. An eyewash station checklist can have numerous benefits: • Ensure the unit is working properly in a time of crisis • Streamline the inspection process • Ensure a consistent and thorough process • Help your facility meet OSHA and ANSI standards. As the designated safety inspector, you should be trained and/or certified in the appropriate OSHA and ANSI standards. You should also stay up-to-date with any new regulations or standards.

ANSI recommends that you inspect your eyewash stations weekly. Compliance Both OSHA and ANSI have requirements for eyewash stations. OSHA is considered the enforcement agency, while ANSI sets the standards. In the case of eyewash stations, OSHA references the ANSI standard, but they do not require compliance with it.

In order to meet best management practices, a good safety program will follow both the OSHA and ANSI standards. OSHA 1910.151(c) states the following regarding eyewash stations: That where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use. OSHA further elaborates on the work conditions that would require an eyewash station or shower in a Letter of Interpretation dated April 14, 2008. The American National Standards Institute’s emergency eyewash and equipment standard (ANSI Z358.1-2014) sets the standard for proper eyewash equipment selection, installation, operation, and maintenance. The eyewash station checklist below covers key points in the ANSI standard in the areas of operation and maintenance. The checklist assumes the unit has been properly selected and installed.

New News

- Download Unlimited Saga Iso Jpn Free

- Forma Akta Perekatki Pozharnih Rukavov

- Transformator Kuldoshina Svoimi Rukami

- Ramki Dlya Fotografij Onlajn More Ramok

- Obrazec Protokola Zasedaniya Komissii Po Raspredeleniyu Stimuliruyuschih Viplat

- Rags Max Schneider Someday Download

- Autocad 2004 Torrent Download With Crack

- Cwcheat Cheatpopsdb Download

- Instrukciya Po Ekspluatacii Kipo Kb308ac

- Laboratornaya Rabota Viyavlenie I Opisanie Priznakov Shodstva Zarodishej Chelov